FAQs

Because someone has already asked…

REGISTRATION

Requirements in each state

COST

The cost of building a trailer yourself

WELDING

Because every weld matters

GLOSSARY

Terms and terminologies

WHERE TO START...

So, you’ve decided to build a trailer. We hope you will find the information in our support pages helpful. A little planning now will go a long way towards making your project a success. We have lots of useful info on cost, trailer design, tools, brakes, axles, registration, safety and are always keen to hear your questions, so don’t hesitate to contact us.

It is best to commence construction only when you have all or most of the required parts on hand

If you are reading this then you probably have a good idea of what type & size trailer you want to build. If you haven’t done so already, consider the max load you will be carrying as well as your car’s towing capacity. Trailers often weigh more than initially thought, so have a look at the TARE and ATM weights in our plan listings to get a good idea of some realistic numbers.

If you are reading this then you probably have a good idea of what type & size trailer you want to build. If you haven’t done so already, consider the max load you will be carrying as well as your car’s towing capacity. Trailers often weigh more than initially thought, so have a look at the TARE and ATM weights in our plan listings to get a good idea of some realistic numbers.

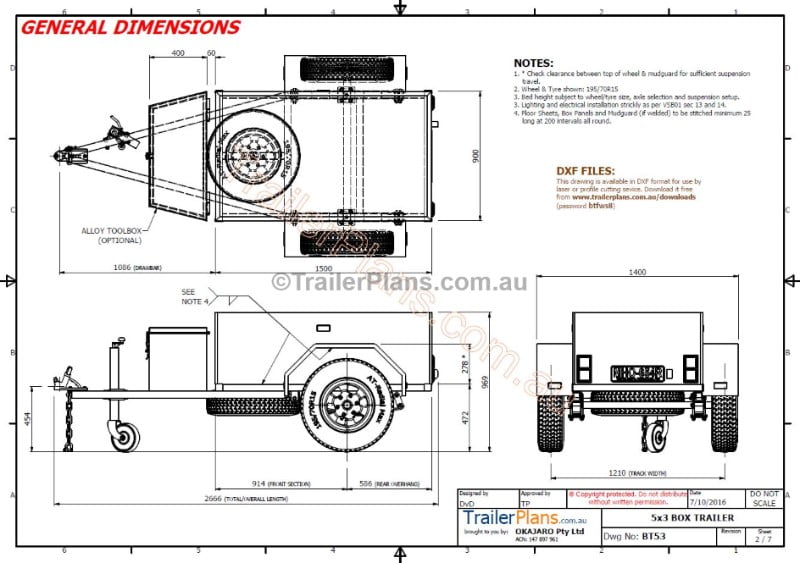

Make a dimensioned sketch or drawing of your design and note steel sizes and lengths. Have a look at other similar trailers to give you some ideas. Find out from you local registration authority what trailer regulations apply and make sure you comply.

TOOLS

Depending on the level of work you wish to perform, below are some of the tools you may need during the construction of your trailer.

- Welding equipment

- Tape measure

- Safety & Protective Gear

- Angle grinder

- Various hand tools

- Work stands (trestles)

- Power Drill

- G-clamps

- Painting Equipment

- Metal cut-off saw

- Large Square

GETTING STARTED

You may choose to approach your trailer project in stages by tackling one major assembly at a time. This not only spreads the cost over a few weeks (or months) but also places focus on the parts at hand and minimizes the amount of material and parts lying around your work area.

Whenever in doubt, ask around. You will find many handy blokes out there who have built a trailer at some stage. Trailer parts suppliers are a great source of information. If you have any queries about the plans or seek clarification, please send us an email or give us a call – our number is in the plans.

Although you do not have to be an expert welder to build a trailer, you will need to be able to apply strong welding with good penetration.

TERMINOLOGY

ADR – Australian Design Rules, national standards that determine minimum vehicle design requirements

Aggregate Trailer Mass (ATM) – Total weight of trailer, including cargo and ball weight

Axle Group – either a Single Axle, Tandem Axle Group, Tri-axle Group, or Close Coupled Axle Group.

Box Trailer – A generic term for any trailer with sides.

Caravan – an enclosed trailer designed primarily for human occupation whilst stationary.

Coupling – Device that joins your trailer to the towing vehicle, ie: 50mm ball, DO35

Dog Trailer – a trailer with 2 axle groups of which the front axle group is steered by the tow vehicle.

Drawbar – portion of a trailer that connects the trailer body to the coupling for towing purposes.

Emergency Brakes – that part of the brake system which automatically applies in the event of trailer break-away.

Gross Trailer Mass (GTM) – Load carried over the trailer axles

Over-Run Brakes – a brake system actuated by the deceleration of the tow vehicle, applying a longitudinal force to the trailer through the coupling.

Pig Trailer – a trailer having one axle group near the middle of the length of the goods-carrying surface.

RAV – RAV (Register of Approved Vehicles) is an online publicly searchable database of vehicles (and trailers) that have met the requirements of the RVSA and been approved for provision to the Australian market. Once your ROVER application has been approved, your trailer should be listed on the RAV.

ROVER – ROVER (Road Vehicle Regulator) is an administration system for the Road Vehicle Standards Act 2018 (RVSA). Before you can register your trailer with your local state authority, it must first be approved on ROVER.

RVSA – The Road Vehicle Standards Act 2018 (RVSA) has replaced the Motor Vehicle Standards Act 1989 (MVSA). The operational aspects of the RVSA are contained in the Road Vehicle Standards Rules 2019 (the Rules). The RVSA, the Rules and other related legislation are collectively referred to as the RVS legislation.

TARE – Weight of trailer only, unladen

Tow ball load (ball weight) – The proportion of trailer weight that is applied vertically to the rear of the tow vehicle.

VIN – A 17-character vehicle identification number (VIN)

VSB1 – Vehicle Standards Bulletin 1, a summary of trailer requirements

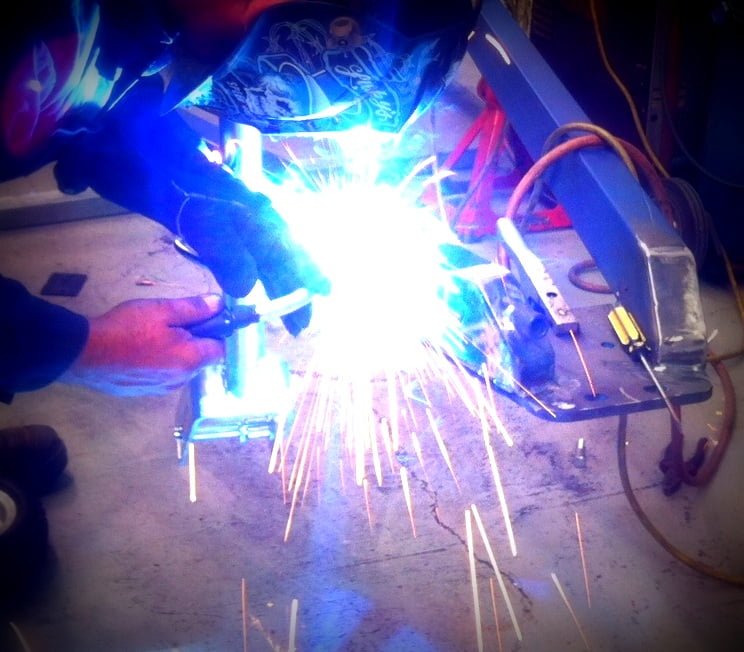

WELDING

Although you do not have to be an expert welder to build a trailer, you will need to be able to apply strong welding with good penetration. If you doubt your ability to make a secure weld, seek some advice from a handy mate or consult some on-line resources. Practice on some scrap off-cuts – preferably the same material size/thickness you will be building the trailer with. Test your practice welds by trying to break them apart.

The drawings supplied with our plans use ISO welding symbols to indicate the recommended weld location, size & length of weld. The symbols are to be used as a guide only. Generally, it is advised to fully weld chassis joints. Body panels can be stitch welded. If in doubt, apply extra welds. If you are unfamiliar with ISO weld symbols, a quick search on the internet will provide plenty of recourses.

WHAT DOES IT COST

Most people that build their own trailers manage to save about 50% of the cost of buying a similar trailer new. In many cases builders save even more if they have some material, parts, wheels or tyres lying around the yard or in the back of the shed. Some have the connections to source steel or parts at reduced prices. Our plans all have complete parts lists that are very helpful in costing out your project well before you commit to building.

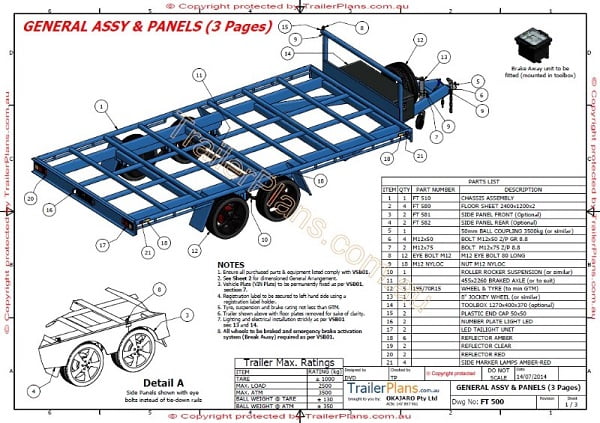

USING OUR PLANS

Once you’ve bought our plans, we suggest you start by reading the guide and printing hard copies of all the drawings, parts lists and instructions. Then, with the parts list as your guide and studying the drawings, plan which parts you will be buying, which parts you will be manufacturing and which parts you possibly already have.

Once you’ve bought our plans, we suggest you start by reading the guide and printing hard copies of all the drawings, parts lists and instructions. Then, with the parts list as your guide and studying the drawings, plan which parts you will be buying, which parts you will be manufacturing and which parts you possibly already have.

Consider the facilities and equipment at your disposal, your budget and availability of suppliers when deciding the extent of manufacturing you will be undertaking. You may then choose to contact suppliers and get an idea of cost and availability of material and parts you need.

It is best to only commence construction when you have all or most of the required parts on hand. At very least, we suggest you have the suspension, axle, wheels/tyres and chassis steel in your possession before commencing construction.

WHAT'S IN THE PLANS

Our chassis and drawbars are made from various rectangular hollow sections (RHS). Material thickness (wall thickness) of RHS is minimum 3mm unless otherwise stated. The Box Bodies detailed in our plans are similar to several commercially available kits and can be sourced from a trailer parts supplier. In most plans the box body kit components are dimensioned and are a useful guide if you wish to manufacture your own body components.

Detailed drawings are provided for components that are commonly manufactured in trailer construction. However, many trailer component suppliers have a range of standard parts that will do the job just as well. As much detail as possible is given for purchased parts, considering that there are a wide range of available components on the market. The information given will assist you with sourcing the hardware you need.

The drawings provide dimensional detail, parts lists and item quantities. Assembly Instructions should be read in conjunction with the drawings.

Information given in our plans, instructions and drawings comply with Australian regulations. A copy of National Code of Practice – Building Small Trailers is provided for your information. Please review the code and ensure your trailer complies with the relevant sections.

USEFUL LINKS

ROVER

Road Vehicle Regulator

RAV

Register of Approved Vehicles

DESIGN REVIEW

CAD viewer software that lets you view, mark up, print, and track changes to CAD files, including DXF files

DRAFTSIGHT

The essential 2D CAD drafting software solution with a familiar user interface, for less that you might expect

VSB1

Trailer regulations that you will need to comply with

ADOBE PDF READER

Adobe Acrobat Reader is the most widely used, reliable, free PDF reader available. View, edit, sign, and annotate PDF documents…